At STAC Industry

we take responsibility

for your product

We accompany you from the

conception of the initial idea,

to the final packaged product.

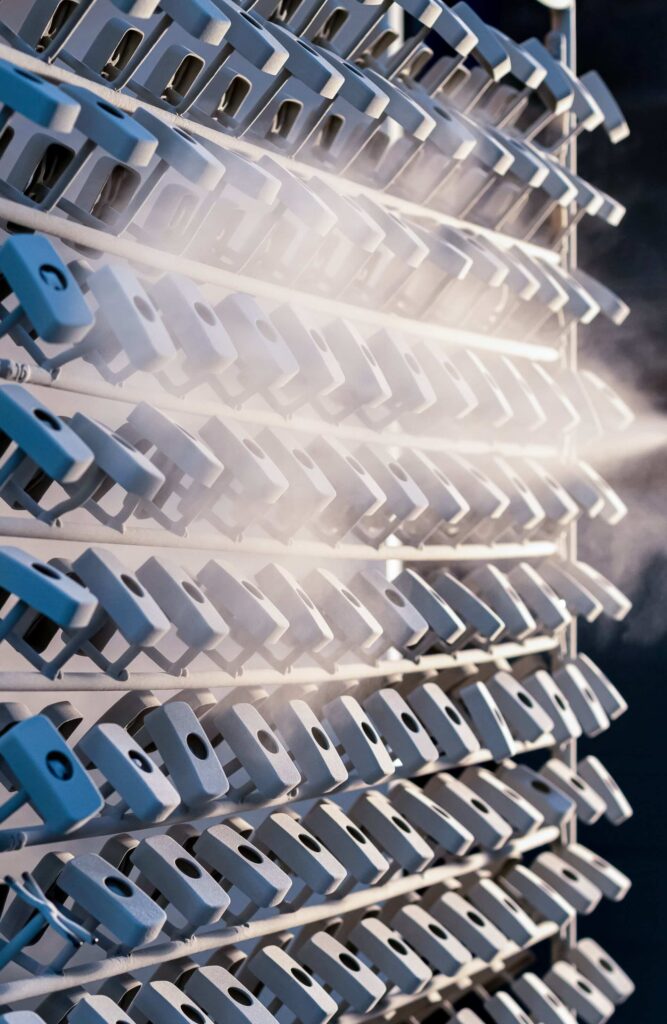

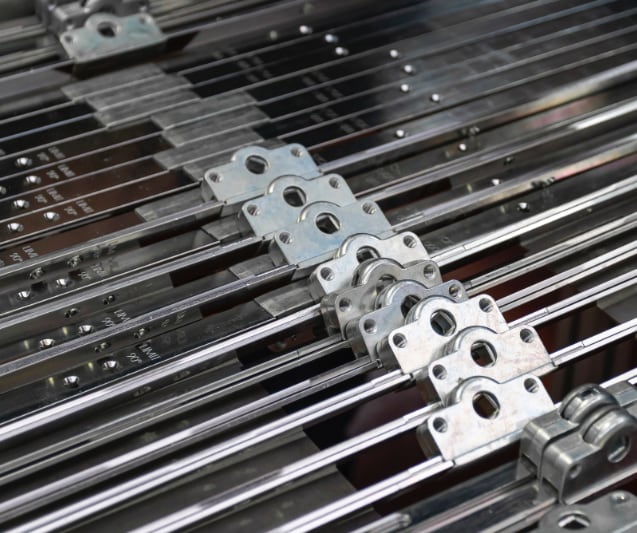

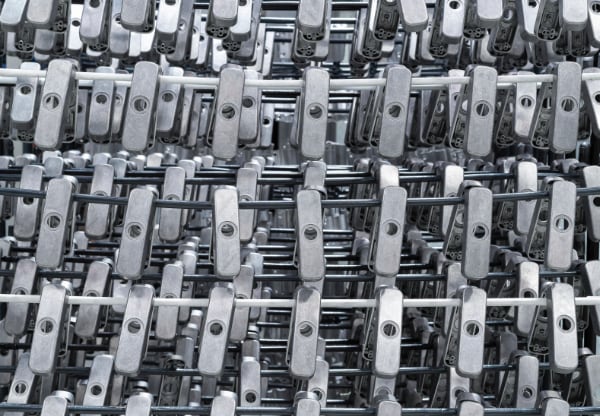

We serial manufacture parts in large quantities with the highest efficiency and lowest cost for customers in a wide range of sectors.

We have a design and industrialization team that will collaborate with you from the first minute on your proposal to obtain the final packaged product, advising you throughout the manufacturing process to achieve your goal.

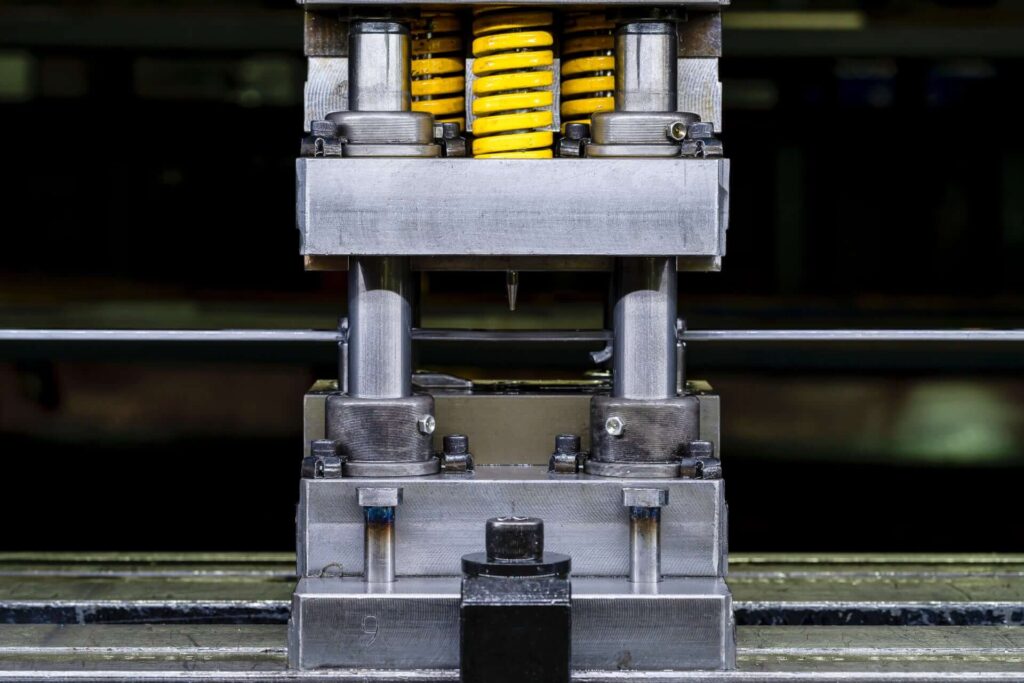

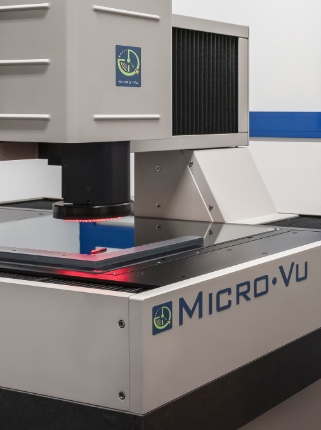

We offer you advanced solutions with the latest automation technologies, the knowledge and experience of our engineering team, working under rigorous quality controls to ensure that all units comply with the required standards and current legislation.

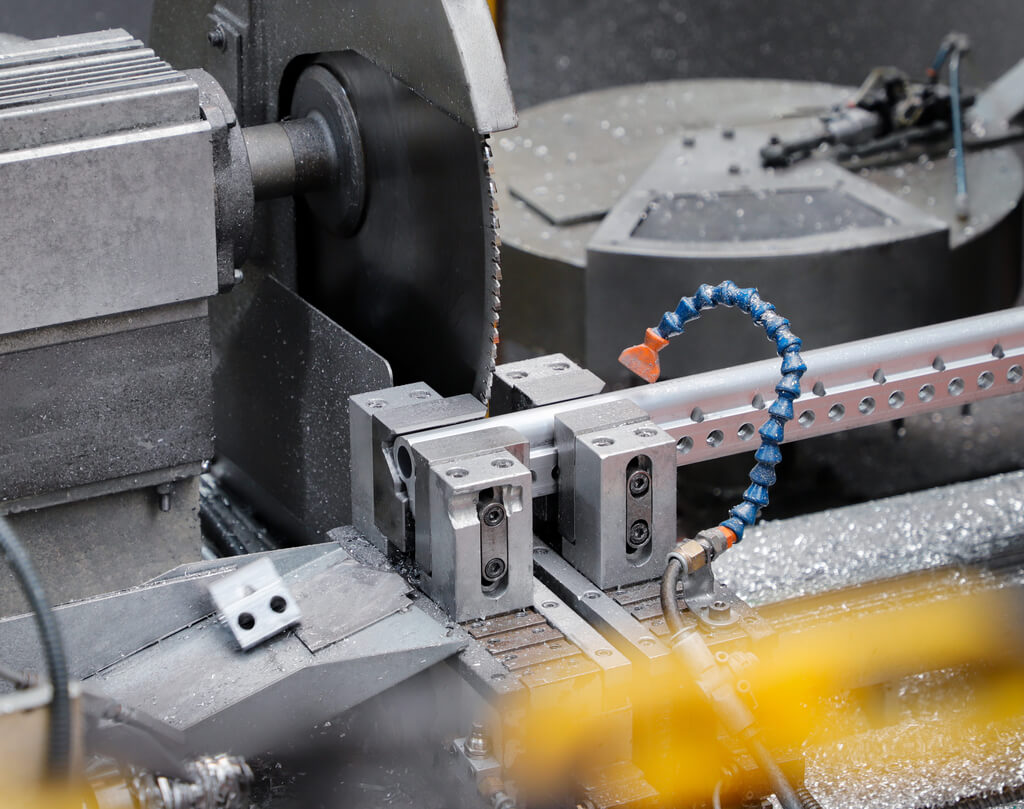

Secondary industrial processes

Once the part is produced, we apply machining processes, mechanical, decorative and protective surface treatments and we take care of the assembly with various methods of union, submitting the parts to quality tests before being packed for distribution.

We have the necessary means for our customers to receive their finished parts and only have to worry about the marketing. Our warehouse and dispatching operators take full care of every product manufactured to ensure that it arrives in the best conditions to our customers.

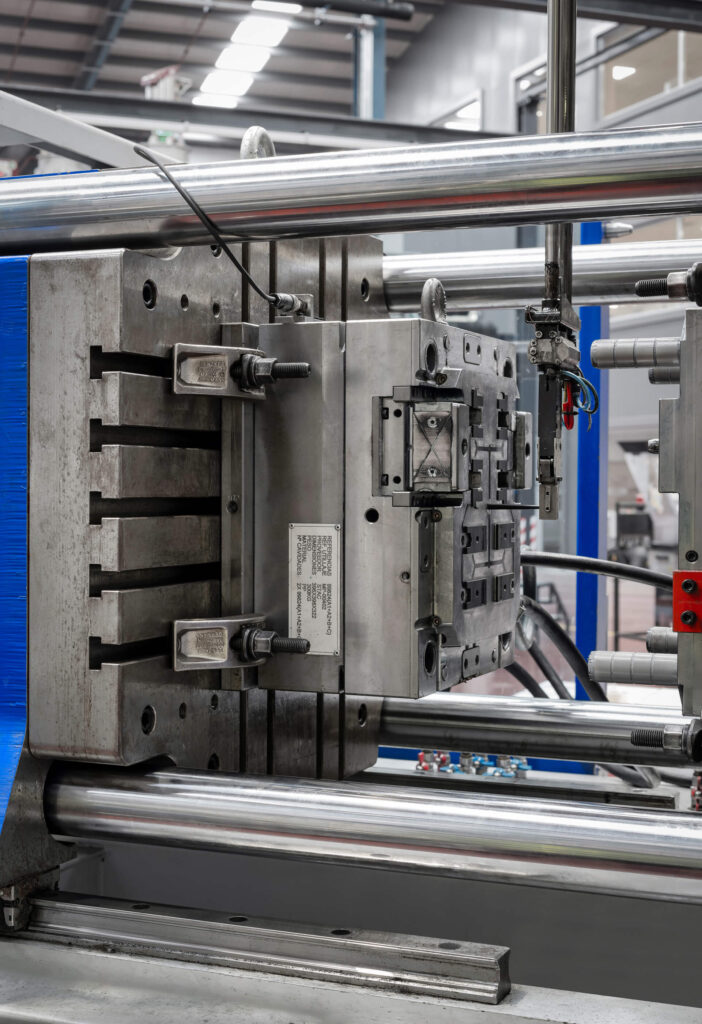

Manufacturing of metal and plastic parts

We develop each piece with the most suitable material according to its production process and final use.

We evaluate the most suitable material according to the mechanical properties necessary depending on the production process and the final use of the components.

We would like to be your comprehensive manufacturing partner

We are ready to work with you and meet the specific requirements of your project.

We manufacture parts for a wide range of industries

Such as architecture, automotive, air conditioning and refrigeration, appliances, electronics, renewable energies, infrastructure, furniture, transport and any sector that requires the serial manufacture of parts.

Our warehouse and dispatch operators take full care of every product manufactured to ensure that it arrives in the best condition to our customers.

Our team

At STAC we have a large, highly-qualified team composed of more than 90 design engineers, materials engineers, chemists, laboratory technicians, process engineers, patternmakers, production operators, quality inspectors, maintenance technicians and packing personnel, all working together to ensure efficient production and to meet the agreed delivery time commitment.

At STAC we approach every idea as an exciting challenge that requires the utmost attention and dedication of our entire team. From part design to final packaging, we will accompany you at every stage of the process to ensure that your needs and expectations are met.

We ensure that everything we manufacture complies with current regulations, because we understand that regulations are critical to our customers.

STAC Industry is more than you see

AUTOMATED PRODUCTION PROCESSES

MORE THAN 90 ENGINEERS

MATERIALS LABORATORY

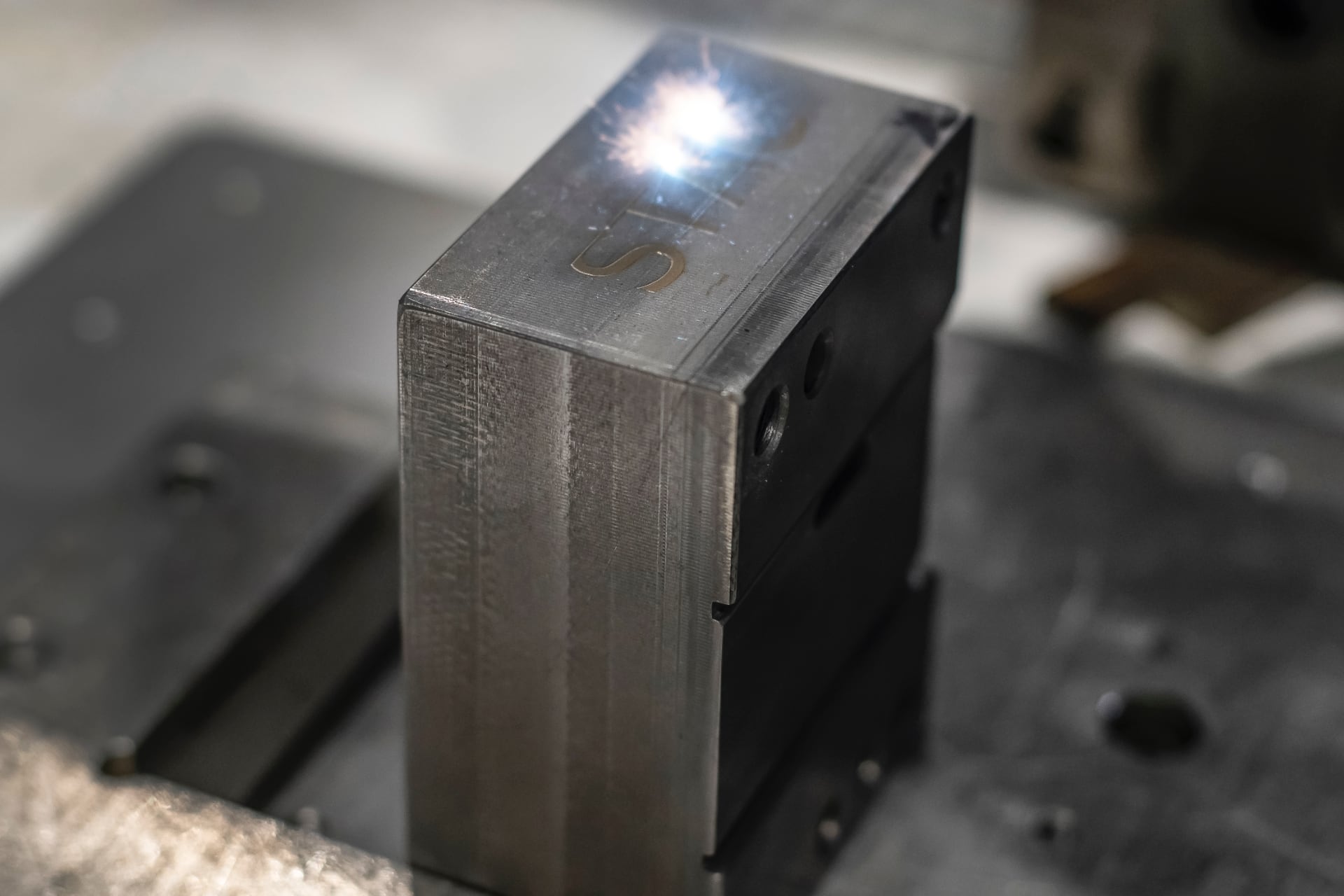

OWN MOULD MAKING WORKSHOP

3D DESIGN AND TOOLING MANAGEMENT PROGRAMS

5-AXIS CNC MACHINES

HIGH PRECISION DIMENSIONAL CONTROL MACHINES

LOGISTICS OPTIMIZATION

Contact us

We’ll be happy to provide help for your projects and resolve any doubts as soon as possible