SECONDARY PROCESSES

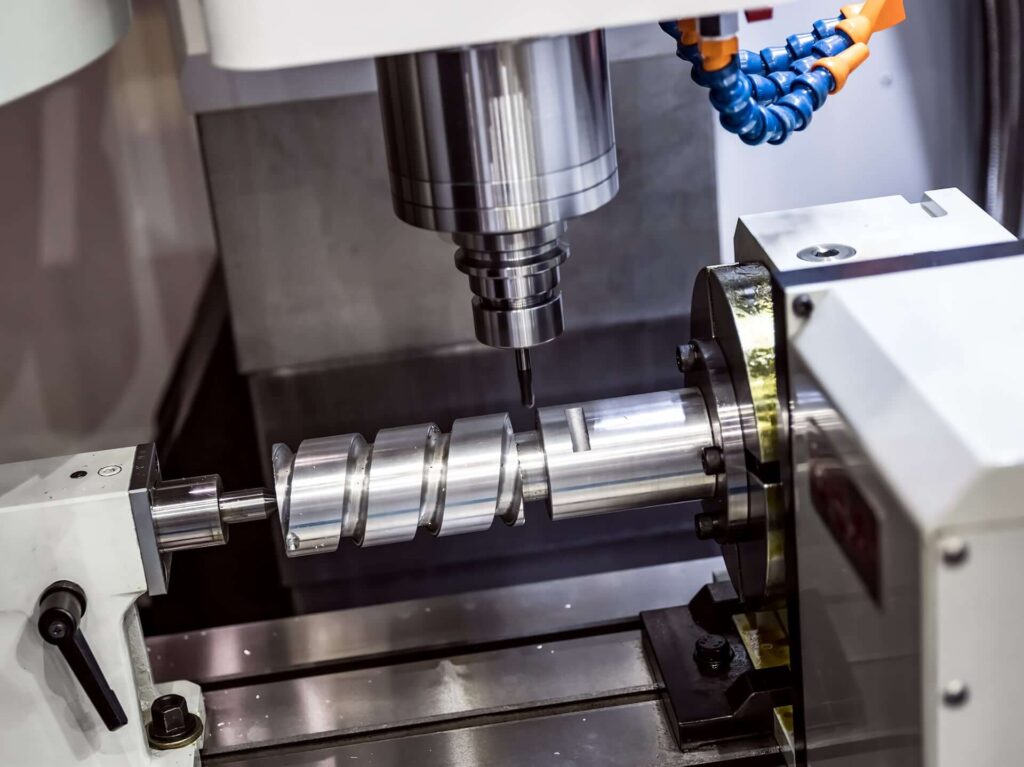

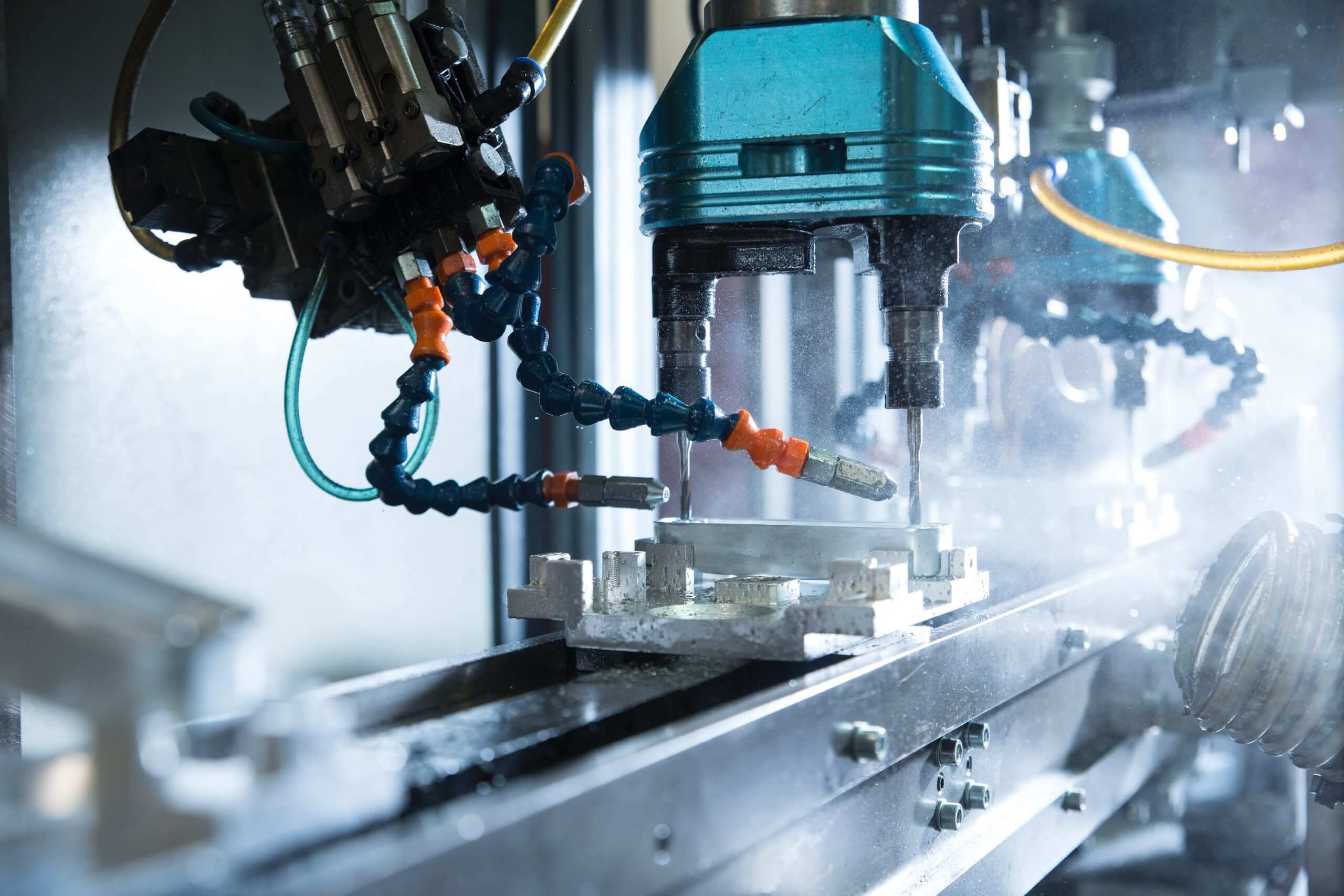

Machining

Machining operations are auxiliary operations that range from those that modify the geometry of the part to give it its final shape, such as: threading, rounding, routing, drilling, etc. even those who seek to provide it with a better finish, or more precision in its dimensions, such as: milling, reaming, planing, etc.

At STAC we have multiple machining machines, with different capacities, both manual and automatic and we have a lot of experience in these industrial processes.

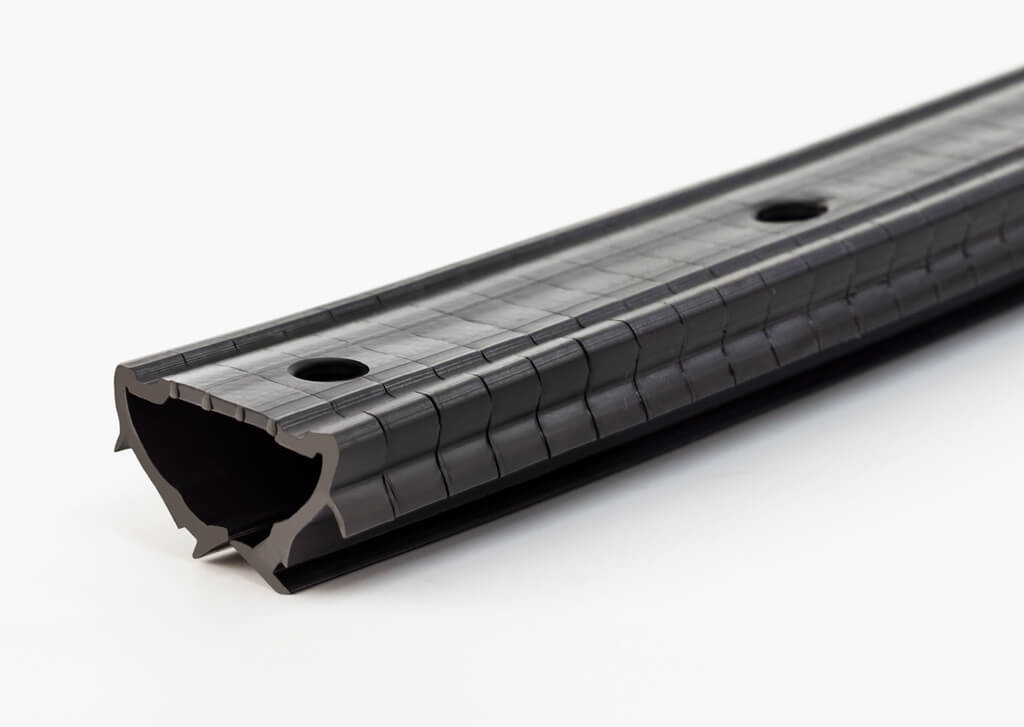

Pre-cut

Pre-cutting is a post-process operation, that is, it is a post-extrusion machining, where the rubber is passed through a system of rollers with blades to make a series of discontinuous cuts on one or several sides of the rubber, and thus produce the pre-cut product.

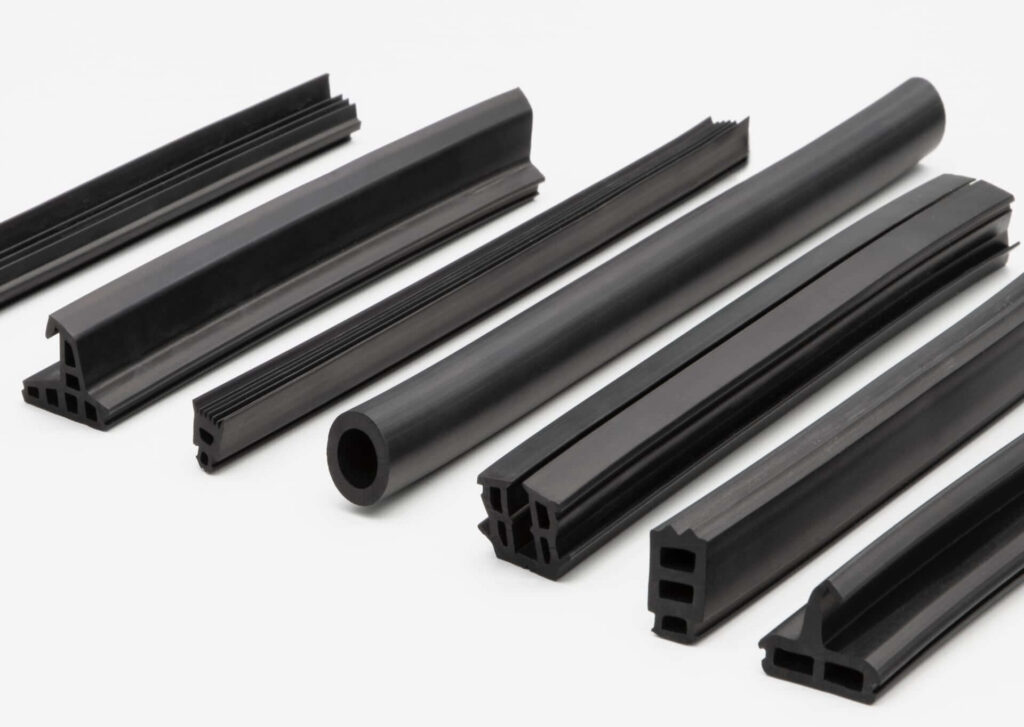

Punch cutting for drainage

This is a type of machining that is performed by cylindrical or slotted dies at the base of U-shaped rubber gaskets for glazing.

Cut into bars

Bar cutting is a process of machining plastic parts that can be done to any piece and any rubber material.

Contact us

We’ll be happy to provide help for your projects and resolve any doubts as soon as possible