INDUSTRIAL PROCESSES

We are experts in manufacturing processes

At STAC, we have a wealth of experience from more than 20 years in the mass production of products using various industrial processes

Process of manufacturing a part

Primary manufacturing processes

We also undertake other production processes, such as lost wax moulding, additive manufacturing, brass forging, laser cutting, MIM injection, gravity moulding and aluminium forging, among others.

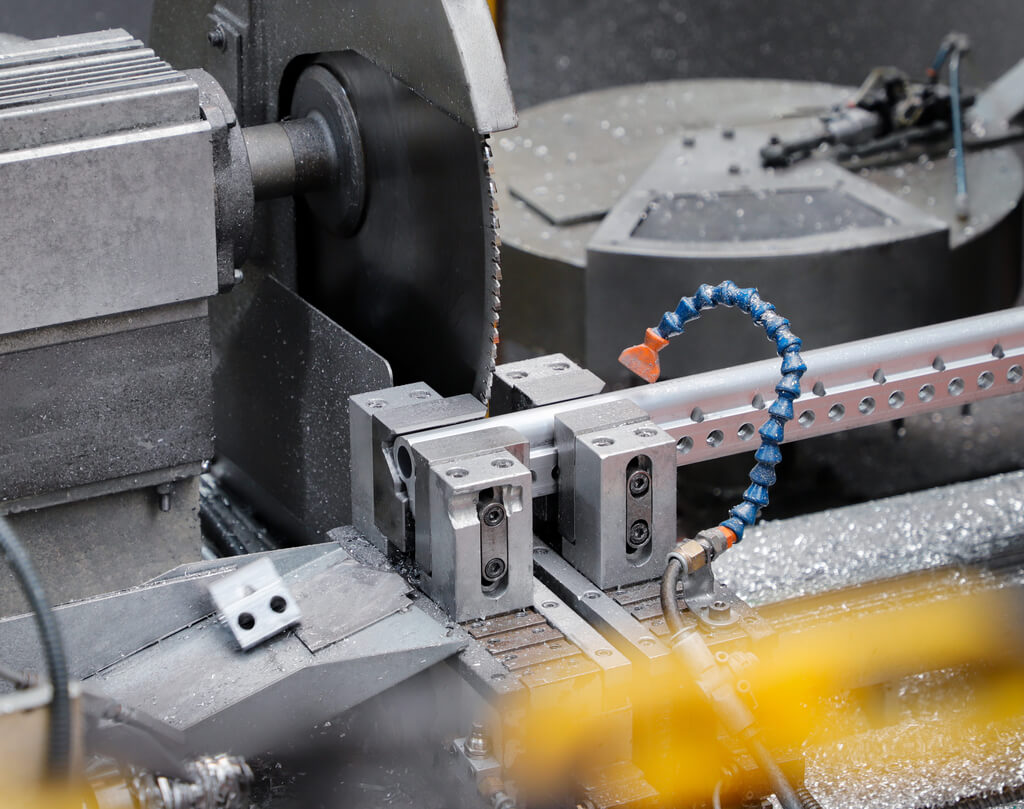

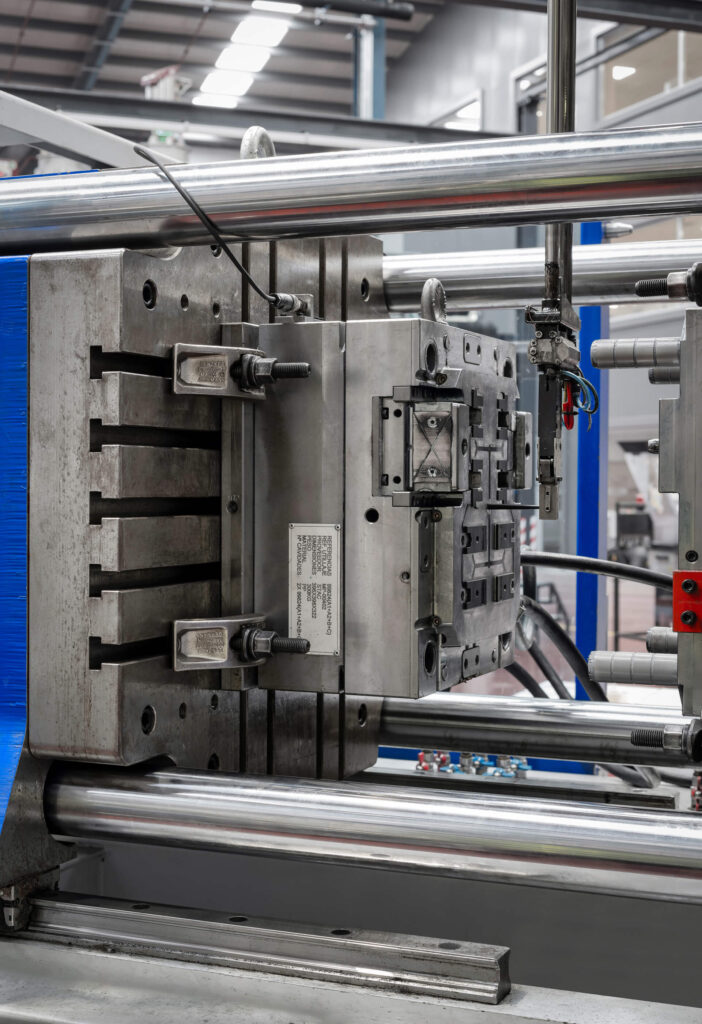

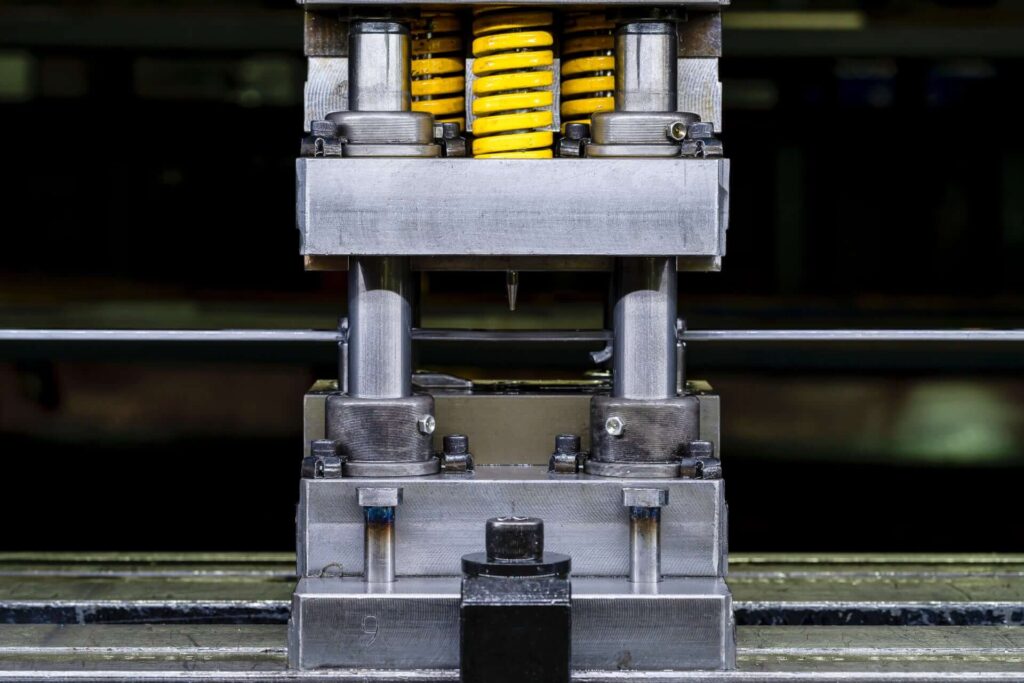

We manufacture our own moulds, dies and tools

We have a tooling department that is responsible for the design, manufacture and maintenance throughout the life of the equipment to ensure repeatability and uniformity in large-scale production.

We produce moulds in our workshop to shape the parts, dies and punches used to cut, bend or shape metal sheets and other accessories necessary for the industrial manufacturing process in order to ensure the precision, quality and efficiency of the process.

We accompany you throughout the process or only at the stage you need

By choosing STAC, you can rest assured that we will be committed to offering bespoke solutions tailored to your project requirements.

Whether you need a one-stop solution for the entire manufacturing process or require our expertise at a specific stage such as Zamak injection, our engineering team is at your disposal to turn your ideas into reality.

If you are looking for a reliable and experienced company, don’t hesitate to contact us.

The importance of secondary processes

A component that is not threaded cannot be mounted; one that is not protected will last less in operation; and if it is not vibrated smooth, it may cause cuts to whoever touches it or present a less uniform final finish.

That is, they are auxiliary processes but decide if the product will be effective or not, and are responsible for adding the final touch of quality that completes the part.

Secondary or auxiliary processes are therefore decisive for a part to meet the technical requirements that will determine its proper functioning and to provide the parts with the necessary quality and finish.

At STAC we understand perfectly well the difficulties of these processes and how to properly tackle each case.

At STAC we are responsible for the entire industrialization process.

When managing your project, we take into account each of the necessary transformations so that the quality of the final product meets the initial requirements.

We know how important it is to take into account from the design phase of the part which secondary processes will be necessary to include in order to avoid last minute inconveniences that could cause a delay.

For example, if we want to apply any coating, we must take into account the extra thickness that we are going to add to the piece, as well as if we are going to mechanically treat the surface.

For machining, the design aspects are crucial to ensuring that the process is executable and as simple and competitive as possible. The same is true for the assembly and joining processes, since it is not the same to design an individual piece that works on its own as it is to design one that has to be mounted and work in harmony with other components within a mechanism.

The clearances, the combination of the different cavities of the moulds, the chain of dimensions, the definition of the adjustment zones, the possible drifts that the processes may suffer; these are some of the concepts with which we work daily and which we are very accustomed to making decisions about.

Do you want to know more about our possibilities?

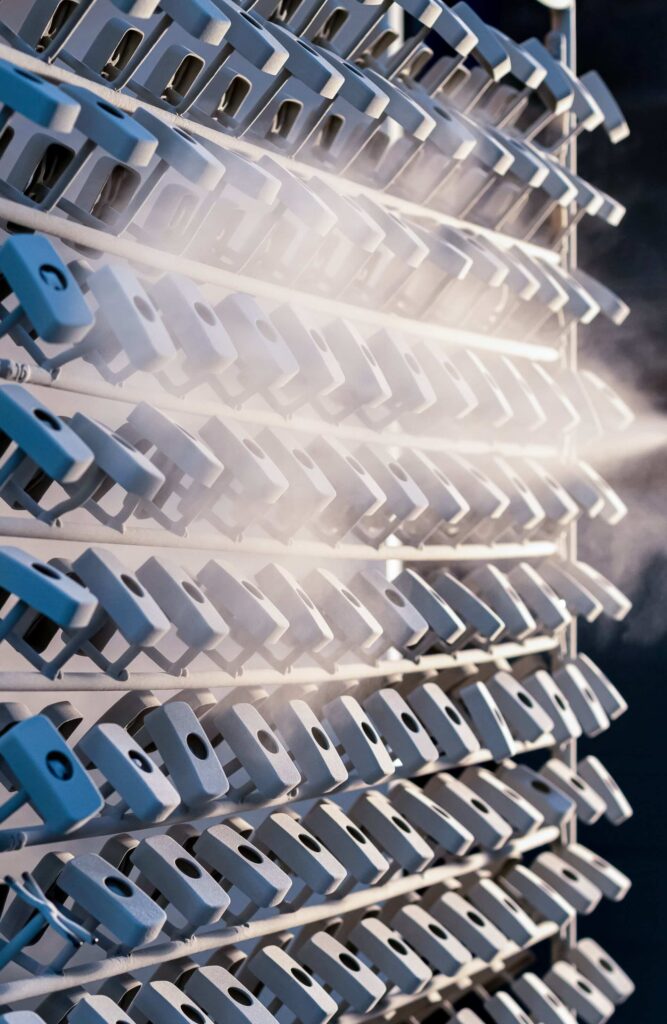

Once the product is finished, the customer only has to worry about receiving the fully-finished parts at the specified address

BOXING AND/OR PACKAGING

As a final operation, STAC offers a wide range of packaging resources, as well as automatic bagging machines, which allows us to offer you the best presentation of your product, as well as the greatest protection for its shipment, which we also take care of.

LOGISTICS OPTIMIZATION

We seek to optimize space and prevent parts from being damaged in transport, but also – and increasingly – we seek sustainable packaging that allows us to meet the demands for quality and optimization of resources as well as respect for the environment.

TRANSPORT

We’ll deliver your components to the place you indicate, palletized as you request.

Comprehensive manufacturing service

We are accustomed to providing a comprehensive service attending to all the details from the conception of the piece to its final delivery.

We evaluate the most suitable material according to the mechanical properties necessary depending on the production process and the final use of the components.

Our commitment to excellence has allowed us to collaborate with clients from various industrial sectors.

Contact us

We’ll be happy to provide help for your projects and resolve any doubts as soon as possible