DESIGN OF PRODUCTS

We turn your ideas into functional designs

STAC’s team of industrial design engineers is committed to your project from the initial conception of the idea, to ensure that mass production of the product is viable.

STAC’s team of industrial design engineers is at your disposal

ANALYSIS OF

REQUIREMENTS

We’ll help you conceptualize your product

MATERIALS AND MANUFACTURING PROCESSES

We’ll evaluate the most suitable solution for each project

DESIGN OF

PROTOTYPES

that allow us to evaluate the technical feasibility and the final appearance of the piece

PERFORMANCE TESTS

Testing functionality and durability allows us to make final adjustments and improvements before mass production

QUALITY CONTROL

to ensure the uniformity and consistency of each product manufactured

Advantages of working with a single supplier during the design and manufacture of your product

You will talk only with one interlocutor and save the time and effort of coordination between numerous different suppliers.

A closer and more collaborative relationship with the factory is established .

Synergies are generated that result in greater economic savings than if you had to contract a supplier for each phase of the project.

Logistics is simplified, avoiding having to transport parts from one supplier to another.

The extensive knowledge and experience of STAC’s industrial design team on production methods, post-production processing and assembly avoids problems of incompatibilities during the process.

By not depending on the timescales of several companies, the delivery time is reduced.

The consistency and quality of the final product is guaranteed by internally resolving any technical difficulties that may arise.

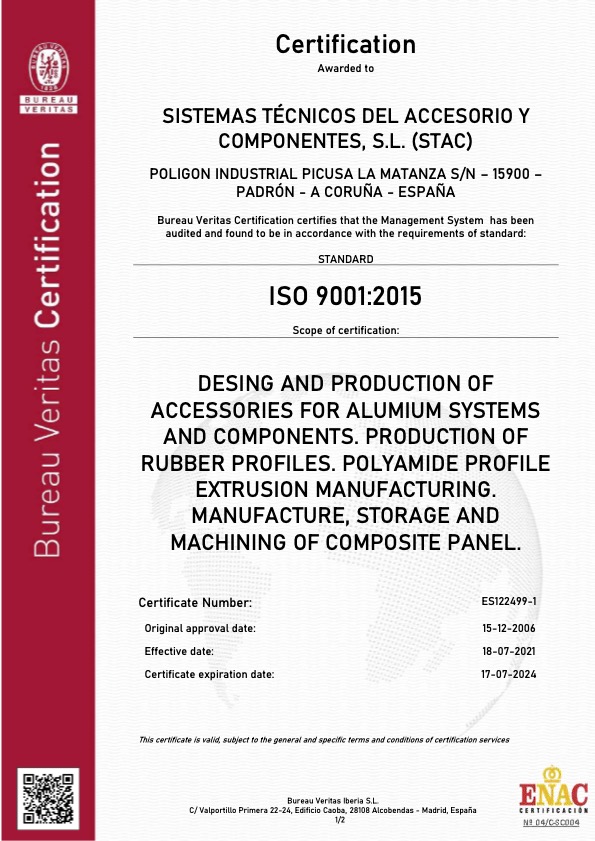

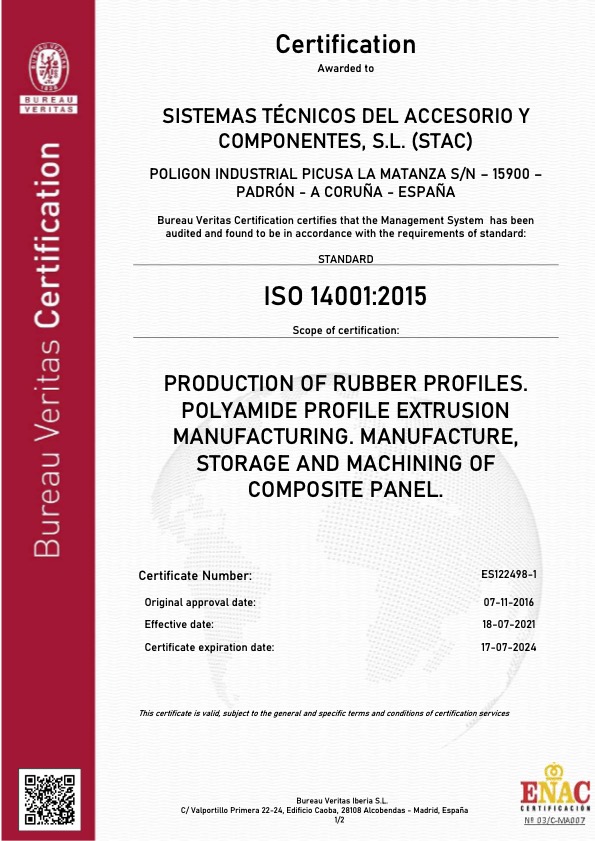

Commitment to quality

We apply objective-oriented quality controls for raw material purchases, production and planning, product and process development, finished product control and fault detection, administration and order processing, logistics and delivery, advice and service, training and staff development, traceability and documentation.

At STAC we develop products in accordance with a wide variety of regulations applicable mainly in Europe and also in other areas of the world. We take advice from and collaborate with the regulatory bodies so they can indicate the tests that the products must pass and what characteristics they must meet to obtain the quality certificates.

Our management systems are certified according to ISO 9001 and ISO 14001 standards.

Commitment to R+D

Our commitment to innovation and development is key to staying ahead of the market. STAC has a materials and testing laboratory that allows us to carry out rigorous tests and analyses on the materials we use for the serial manufacture of products, allowing us to select the best ones for each application and ensure the quality of the products we manufacture. It also allows us to develop new products and manufacturing processes that improve our efficiency and reduce production cost.

We constantly introduce new ideas, technologies and methods that allow us to achieve significant advances in the use of new materials, use of more advanced machinery, use of more efficient manufacturing techniques, etc.

The implementation of Industry 4.0 technologies such as artificial intelligence and robotics, allow us to further automate and optimize our processes, which has increased the efficiency and accuracy of production.

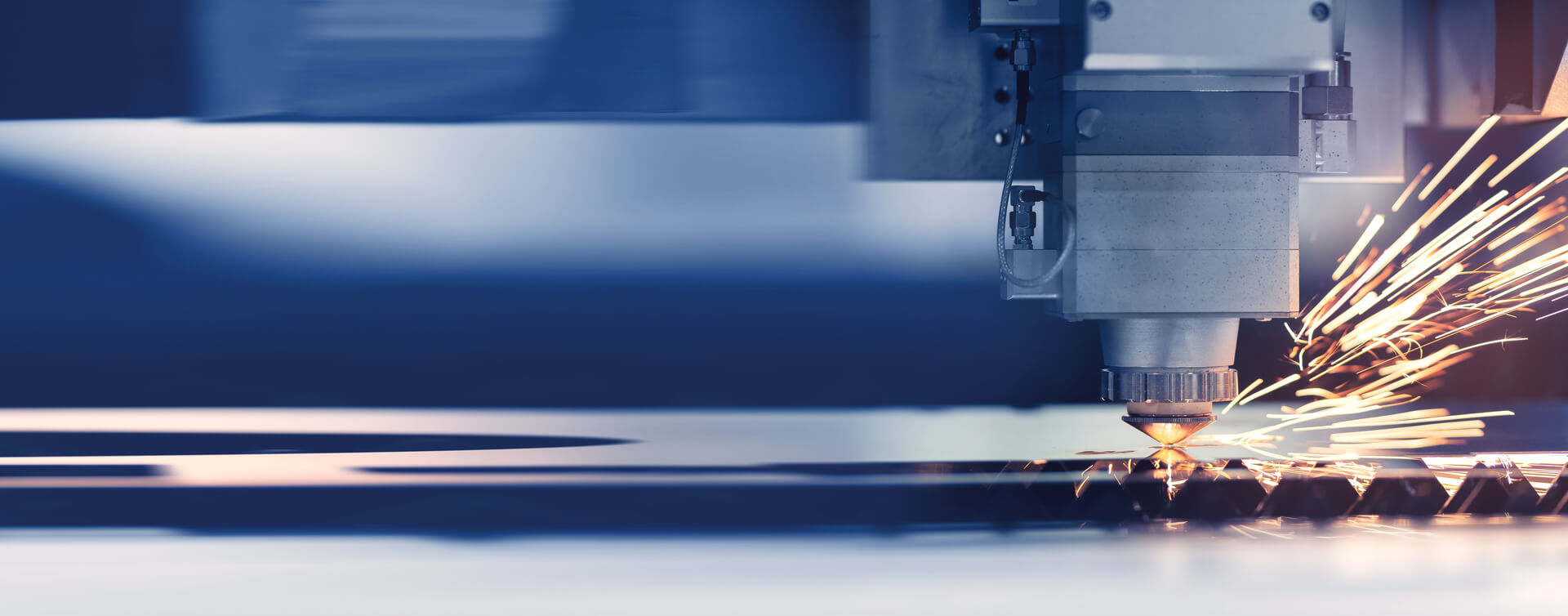

We industrialize your projects

We serial manufacture your product using specialized tools and machinery to ensure quality and efficiency in the process.

At all times, we are governed by sustainability criteria, we carry out an assessment of the product life cycle from cradle to grave, including the assessment of environmental impact, safety and occupational health during the manufacturing process.