SECONDARY PROCESSES

Assembly

Assembly processes are those that allow the various components to be combined to create a complete product. At STAC we have expert teams that will guide you in the processes necessary for the assembly of all types of parts.

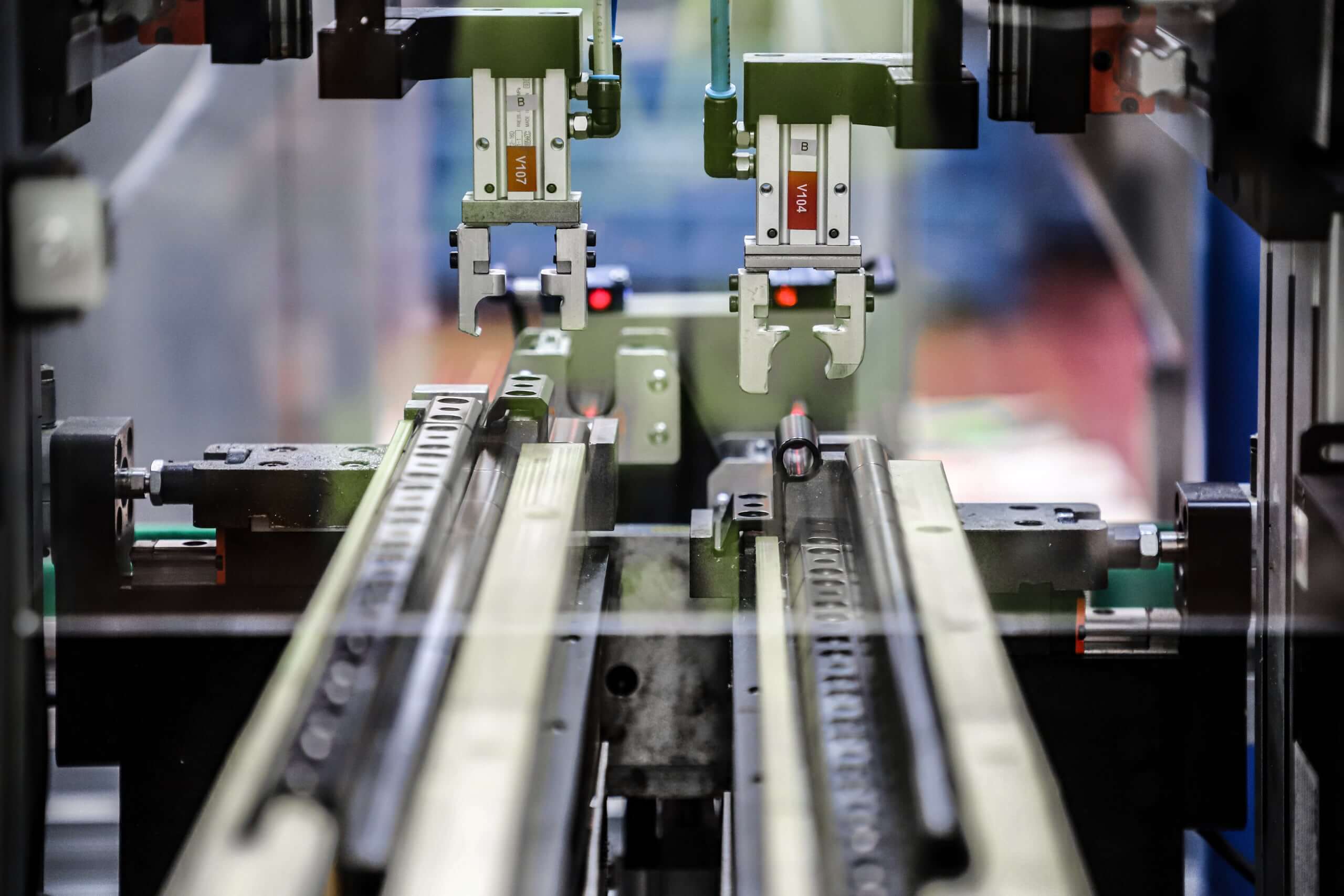

Joining technologies

Joining technologies are those that allow parts tobe joined together to form systems or assemblies. These technologies range from threading, through riveting, adhesive, and pressing. At STAC we have manual and automatic assembly lines.

Installation

Our experience allows us to know the difficulties and problems associated with the different types of joints, and how to guarantee the correct execution of the installation or mounting of the pieces. This makes it easy for us to ship assembled products, ready for immediate installation at their destination.

Welding

Welding is a bonding process used in the assembly of parts that involves the fusion and bonding of materials through the application of heat. In welding, a heat source, such as a flame, electric arc or laser, is used to melt the ends of the pieces to be joined, and a filler material, called filler metal, is added to form a solid connection.

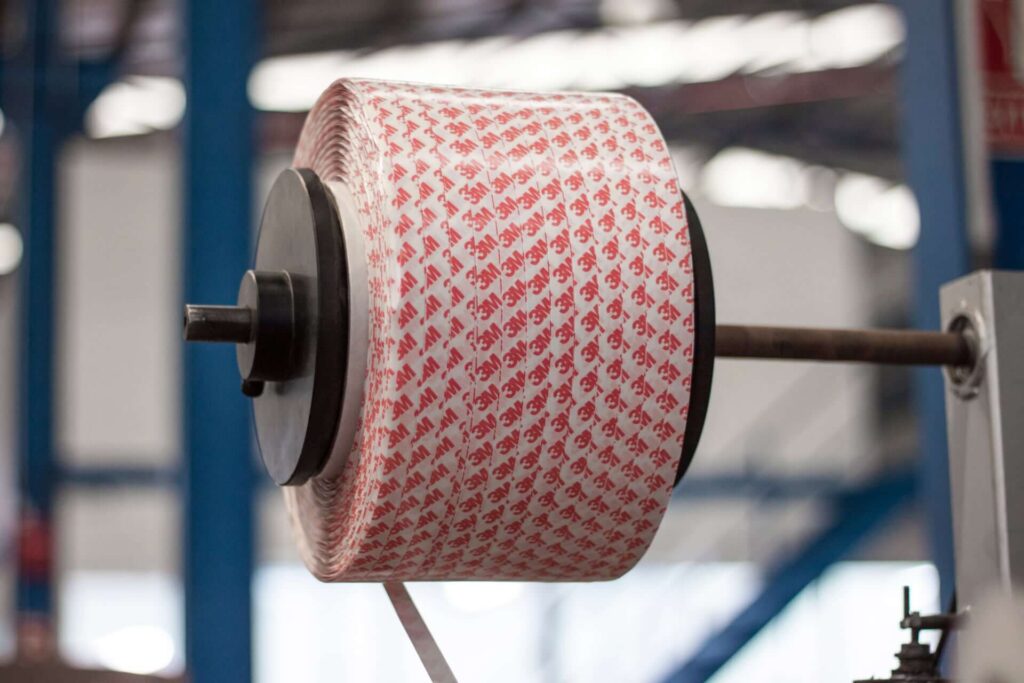

Adhesion using double-sided tape

Sometimes it is necessary to glue a gasket or seal to a door or window system which does not have a slot profile to allow mechanical attachment of the product in the system. For these specific cases, adhesive is an efficient solution. It involves adding a double-sided adhesive tape to the rubber to stick it against the desired surface and thus seal the system.

Anti-stretch cord insert

The anti-stretch cord insert is an assembly solution that can be optionally added to all joints that have a clip and which are pressed in to the mating slot.

The cord, which can be of various materials, such as fiberglass or nylon, is added to the product during its extrusion, and is integrated inside the piece throughout its length. The purpose of this cord insert is to offer tensile strength to prevent the rubber from stretching when it is being subjected to tension during mounting.

This process solves the problem of the rubber joints stretching during the assembly process, which since they are elastomers, tend to recover their original length, leaving a small, uncovered space in the aluminium profile after a while.

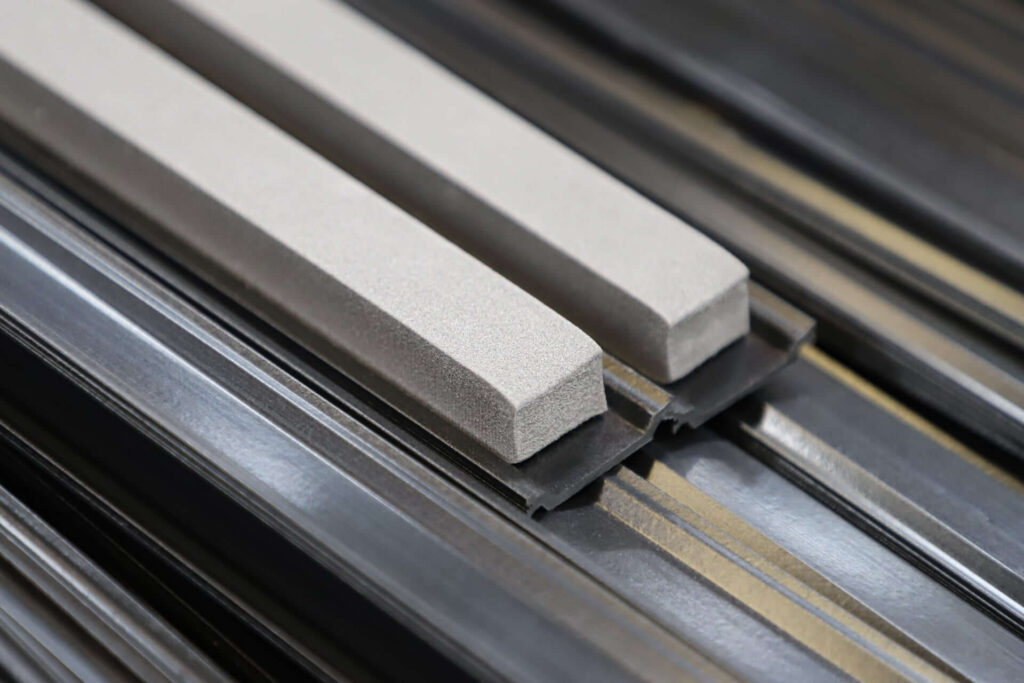

Foaming glues in polyamide profiles

In certain systems where thermal performance needs to be improved, foam profiles need to be added to reduce convection energy losses in the chambers between the profiles.

Contact us

We’ll be happy to provide help for your projects and resolve any doubts as soon as possible