PRIMARY PROCESSES

High-pressure aluminium injection casting

At STAC we are specialists in the manufacture of injection cast aluminium parts and we accompany our customers from conception through to the mass production of the desired part.

PRIMARY PROCESSES

High-pressure aluminium injection casting

At STAC we are specialists in the manufacture of injection cast aluminium parts and we accompany our customers from conception through to the mass production of the desired part.

What is Aluminium Injection?

High pressure aluminium injection is a process used in the casting industry to manufacture aluminium parts with high precision and quality. HPDC (High-Pressure Die Casting)

In this process, aluminium is melted at 700°C and injected under high pressure into a special steel mould.

Inside this mould the negative of the piece called the “cavity” is engraved.

The high pressure allows the liquid aluminium to completely fill the mould cavity and acquire the desired details and characteristics.

Advantages of Aluminium injection manufacturing

High pressure aluminium injection offers several advantages compared to other manufacturing processes of aluminium parts such as gravity casting or machining parts from an aluminium block:

It allows the production of complex parts with thin walls, fine details and smooth surfaces.

In addition, the process is fast and efficient, which makes it suitable for mass production.

The resulting parts are lightweight, resistant and have superior mechanical properties to those made by gravity casting.

Sectors which use Aluminium injection

This method is used in a wide range of industries, such as automotive, aerospace, electronics and construction, to manufacture components such as engine casings, structural parts, transmission components, pump housing, among others.

At STAC we are specialists in this process and we accompany our customers from the initial idea to the final product.

Do you want to know how?

Frequently asked questions about aluminium injection

The pressure injection process requires alloys to have high fluidity, therefore only some of the aluminium alloys are suitable for manufacturing parts using this process.

Here are some of the main alloys used:

- Aluminium alloy EN AC-46000 (AlSi9Cu3): This is a very versatile aluminium alloy and widely used in die casting. It has good fluidity, excellent corrosion resistance and high tensile strength. It is used in automotive, electronic and construction applications, such as motor housings, electrical components and support structures.

- Aluminium alloy EN AC-46100 (AlSi12Cu): This alloy has a higher strength than EN AC-46000, making it suitable for applications requiring greater rigidity and mechanical strength. It is used in structural parts, transmission components and other applications where increased load and fatigue resistance are required.

- Aluminium Alloy EN AC-46200 (AlSi10Mg): This alloy has excellent fluidity and surface finish characteristics. It is ideal for parts that require high precision and an aesthetic finish, such as electronic device housings, lighting parts and furniture components.

- Aluminium alloy EN AC-44300 (AlSi12): This alloy has a good combination of fluidity, mechanical strength and corrosion resistance. It is widely used in the automotive industry for parts such as gearboxes, engine mounts, intake manifolds and other structural components.

For the correct definition of the alloy it is necessary to know the final use of the part, its surface finishes, the corrosion resistance requirements, the minimum and maximum thicknesses that the piece should have, … and many more things.

Do not worry, if you want to know more about this point, please contact us.

Remember that aluminium enters the injection mould at about 700ºC. At this temperature most steels lose their mechanical characteristics, because the heat modifies their internal structure.

That is why aluminium injection moulds have to be manufactured with steels for high-temperature work, and these are very special and very expensive. Before entering service and while being machined, they have to be subjected to various, highly-controlled heat treatments, so that their characteristics are optimal.

At STAC we have a tooling manufacturing department that is responsible for the design and manufacture of the moulds and their maintenance throughout their service life.

Some of the most important features to consider are:

- Materials for the different parts of the mould: These materials must be sufficiently strong and durable to withstand the high pressures and temperatures of the injection process.

- Moulding plates: The mould consists of a cavity and a core that define the shape of the part to be injected. These parts must be precise and have a high quality surface finish to ensure reproducibility and quality of the parts.

- Cooling system: The aluminium injection mould must have an efficient cooling system to control the mould temperature during the process. This helps ensure proper solidification of the aluminium and an efficient production cycle.

- Feed channels and overflows: The mould must have feed channels to allow the entry of the melted aluminium into the mould cavity. In addition, overflow areas are required at the perimeter of the mould to assist in the evacuation of air and impurities during the injection process.

- Wear resistance: Since cast aluminium can exert significant pressures and forces on the mould, it is essential that the mould has adequate wear resistance and that interchangeable inserts are considered for the weaker parts of the tooling. This ensures long mould life and consistent part quality.

Aluminium moulds are perhaps the most technical tooling that we manufacture and the ones with the most critical maintenance.

STAC guarantees its customers the mould during the life of the tooling.

If you want to know more about this point, we help you. Contact us.

To manufacture injected aluminium parts with the highest quality, our machines have the following characteristics:

- High pressure and closing force: the machine must be able to generate and maintain high injection pressure to ensure proper filling and compacting of aluminium in the mould. In addition, it must have enough closing force to keep the mould safely sealed during the process.

- Precise temperature control: the machine must have a precise temperature control system to ensure that the cast aluminium maintains the right temperature throughout the injection process, from smelting to injection time. This helps to avoid problems such as premature cooling or thermal imbalances that may affect the quality of the part.

- High precision injection and dosing system: the injection and dosing system must allows precise control of the volume and injection rate of the melted aluminium into the mould. This ensures a uniform distribution of the material and avoids problems such as porosity or filling defects.

- Injection pressure and speed control: the machine must have sophisticated controls that allow precise adjustment and control of injection pressure and speed. This is essential to adapt to the specific characteristics of aluminium and part design, thus ensuring optimal injection and minimizing defects.

- Monitoring and logging capability: It is important that the machine has monitoring and data logging capabilities to allow detailed tracking of process parameters such as temperature, pressure, speed, times, among others. This facilitates the identification of potential problems and contributes to the continuous improvement of the manufacturing process.

- Gas extraction system: Since aluminium injection can generate gases and bubbles during mould filling, the machine must have an efficient gas extraction system. This helps to minimize porosity and improve the quality of parts.

- Robustness and stability: The machine must be robust and stable to withstand the high pressures and temperatures of the aluminium injection process. This includes a solid structure, high-strength components and reliable clamping and closing systems.

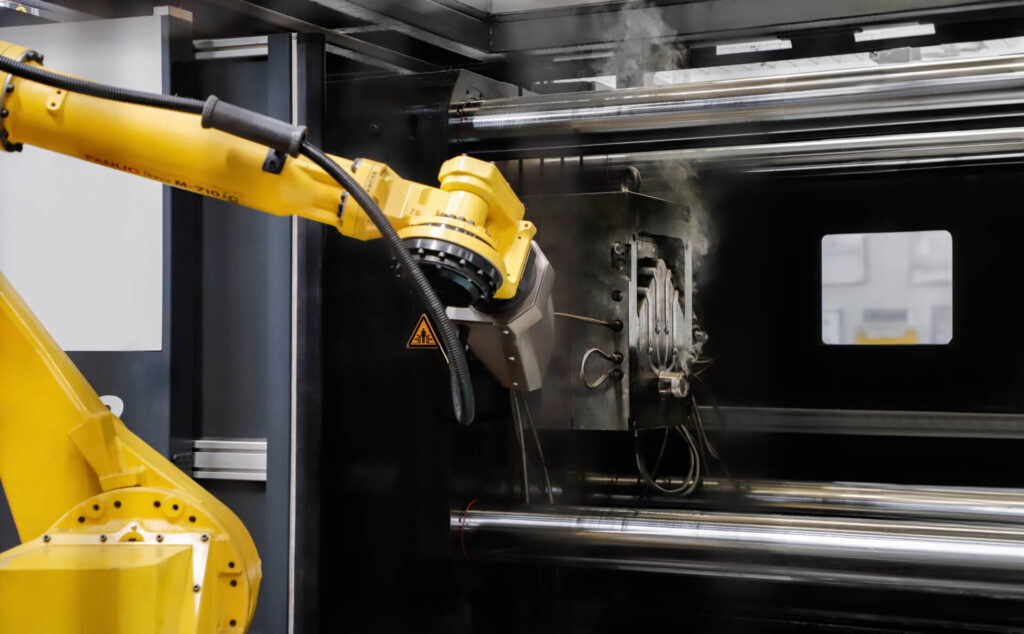

- Safety: Our machines are fully robotised so that no worker comes into contact with the smelted aluminium.

If you want to know more about our aluminium injection capabilities, please contact us.

Comprehensive solution for manufacturing injected aluminium parts

Our comprehensive approach means we take care of every stage of the manufacturing process of injected aluminium parts, ensuring quality and efficiency at every step.

Below, we summarize the main services we offer.

At STAC, we want to be your comprehensive supplier of injected aluminium parts.

We want to provide you with a comprehensive service and we take care of the entire process, from the initial design to the final delivery of the finished product where you request it.

Our priority is to help the customer achieve their goals

At STAC, we are committed to excellence and customer satisfaction.

We are ready to work closely with you and meet your specific requirements.

Don’t hesitate to contact us to discuss your projects and how we can help you achieve your goals.

Post-aluminium Injection processes

After the aluminium injection process, it is common to perform a series of subsequent processes to obtain the final parts with the desired characteristics.

The most common post-casting manufacturing processes are the following:

Deburring

It consists of removing burrs, sharp edges or unwanted protrusions from the moulded piece. This can be done by manual or mechanical methods, or using specialized machinery.

Contact us

We’ll be happy to provide help for your projects and resolve any doubts as soon as possible